N'hésitez pas à envoyer un message

Ningbo Yinzhou HENTACH électromécanique Co., Ltd. (Anciennement Hengtai Motor) Créé en 1995 et anciennement connu sous le nom de « Hengtai Motor » (le nom chinois de notre société), nous avons officiellement adopté le nom anglais « HENTACH Motor » en 2020. Les deux noms représentent le même fabricant de confiance dédié à l'innovation électromécanique depuis plus de 30 ans. Spécialisés dans le moulage et le traitement de précision de moteurs à courant continu miniatures, de moteurs de moyeu électriques/motos et d'alliages aluminium-magnésium pour véhicules électriques, nous combinons un système de contrôle qualité ISO 9001 rigoureux, des pratiques de gestion matures et des équipements de fabrication/test de pointe pour fournir des solutions fiables.

With end-to-end capabilities spanning from raw material casting to final product delivery, we serve diverse markets including e-bikes, cargo vehicles, AGVs, golf cars, agricultural machinery, and e-karting. Our 9,000+㎡ campus (5,000㎡ built area) houses over 60 units of advanced production equipment, including 500-ton die-casting machines, precision CNC machine tools, laser marking systems, micro-arc oxidation lines, and two dedicated electric vehicle motor test benches. This infrastructure ensures efficient production and strict compliance with international quality standards.

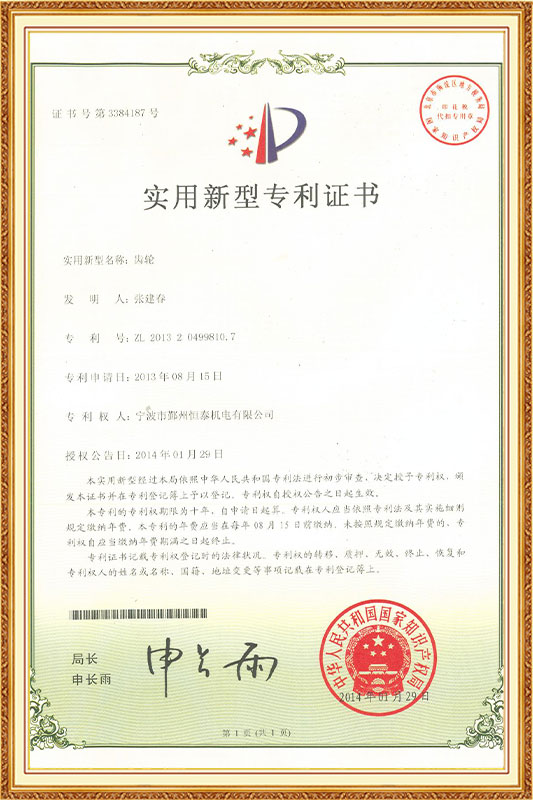

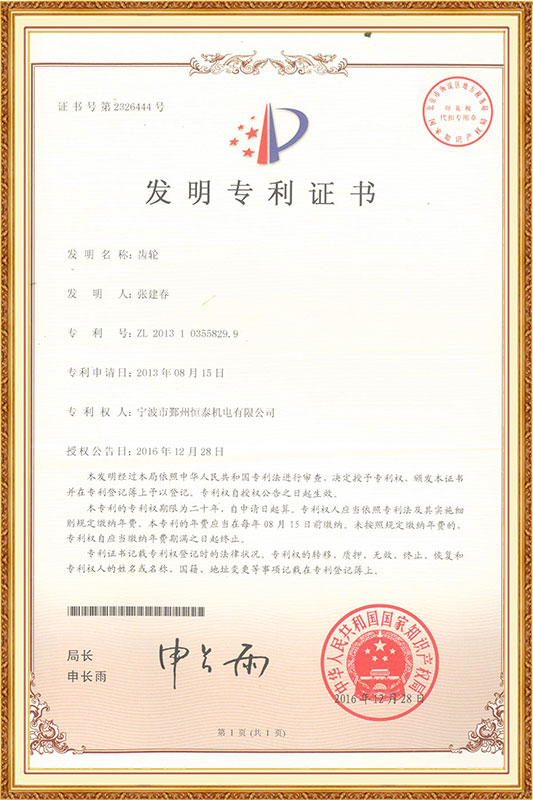

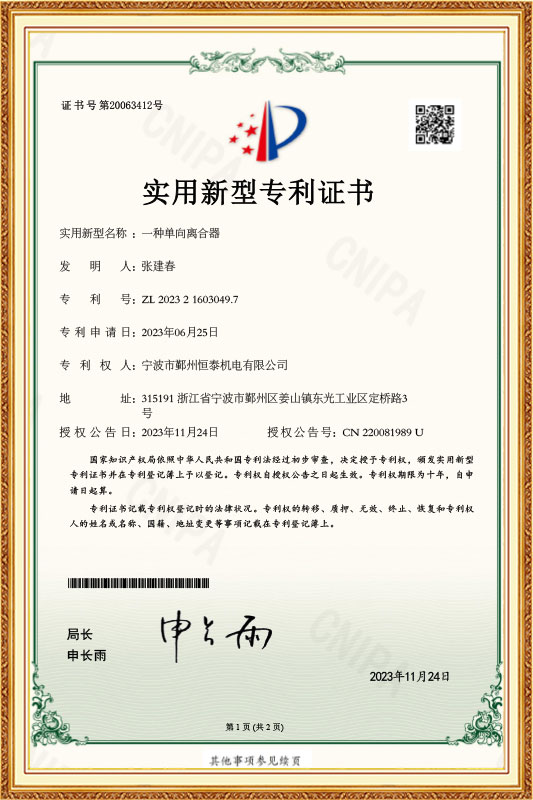

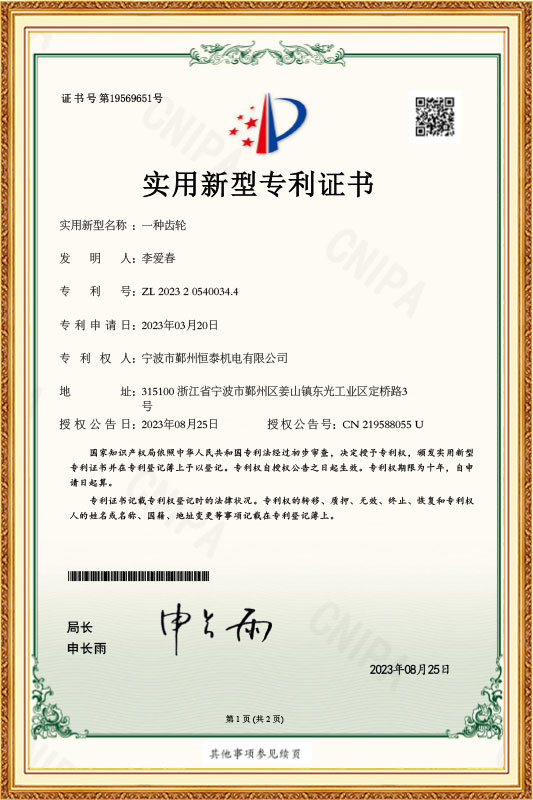

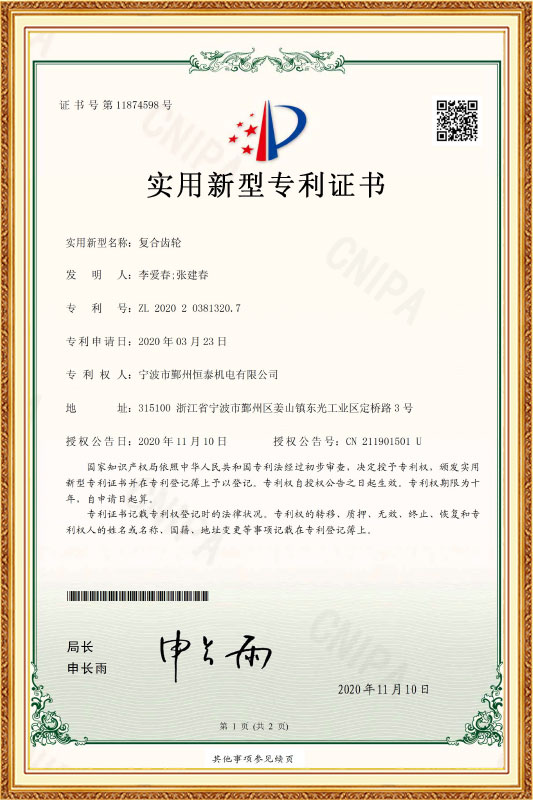

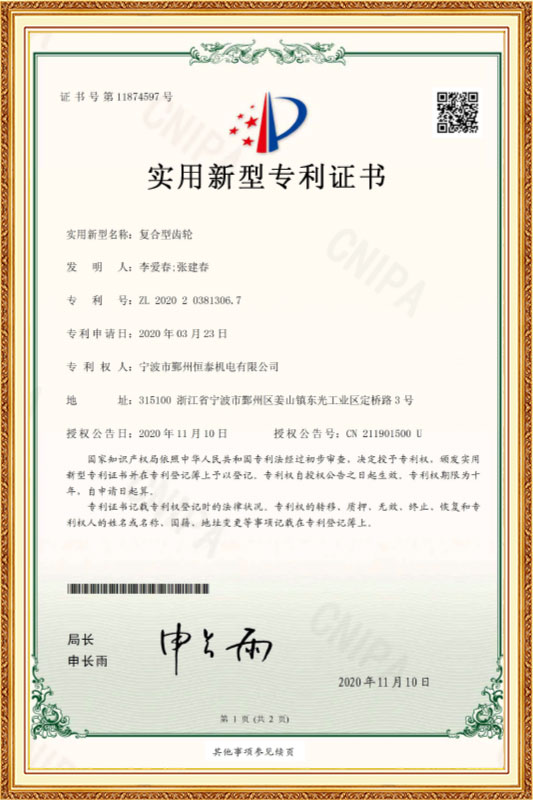

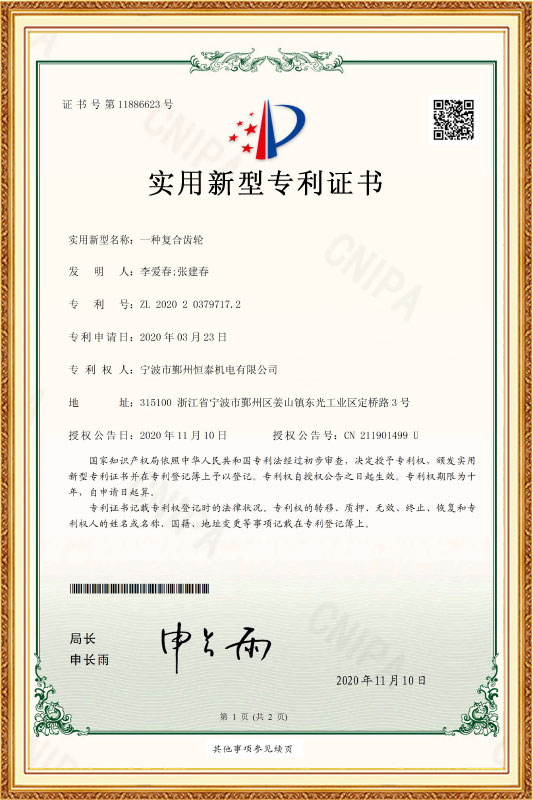

Chez HENTACH (Hengtai), nous accordons la priorité aux matériaux de haute qualité et à la technologie exclusive : notre engrenage en nylon-acier breveté témoigne de notre excellence en ingénierie. Pour valider la durabilité, nous avons lancé un programme de garantie de kilométrage pour les moteurs dépassant 30 000 miles. Le résultat ? Plus de 50 moteurs ont non seulement atteint cette référence, mais l'ont même dépassée, certains atteignant une distance impressionnante de 50 000 milles. Ces performances concrètes reflètent notre souci constant de la fiabilité et nous motivent à innover continuellement pour des solutions de moteurs plus intelligentes et plus solides.

Faites confiance à la marque connue dans le monde entier sous les noms de Hengtai Motor et HENTACH Motor, où l'innovation brevetée des engrenages en acier rencontre une durabilité éprouvée.

Electric fat tire wheel hub motor: the power center in extreme terrain

In the field of electric two-wheeled vehicles, especially electric fat tire vehicles, the development of wheel hub motor technology is constantly breaking through performance bottlenecks such as complex terrain, heavy-load scenarios and long battery life. Among them, E-Fat Tire Hub Motor, as a motor system designed for extreme road conditions, is becoming a key choice for many brands and users.

E-Fat electric fat tire vehicles are widely used in complex terrain riding such as sand, snow, and mountains, as well as heavy-load use scenarios such as agricultural and forestry ranch transportation and mountain express delivery with their wide tire design, super grip and excellent off-road capabilities. Personalized customization needs of urban trend commuting and leisure sports enthusiasts

These applications determine that its motor must have three core performances: high torque, high power, and high reliability. In low-adhesion or high-resistance terrains such as beaches, mud, snow, or gravel mountain roads, only motors that output sufficient torque can ensure that the wheels are effectively driven. Facing steep slopes of 20~30%, high-torque motors can achieve continuous power output to prevent "slipping" or "stuck". When starting under full load, torque is the key to determining whether the vehicle can start smoothly. Low-speed high torque helps maintain stability on slippery or soft surfaces and improve riding safety. Electric fat tire vehicles need to have long battery life, high speed and strong power output capabilities in most scenarios. Especially in commercial scenarios such as farm logistics, forest transportation, and express delivery, long-term high-load operation is the norm. High-power motors (such as 1000W~2000W) not only provide stronger acceleration and climbing capabilities, but also better support heavy-load conditions such as double riding and cargo consignment. At the same time, with large-capacity batteries, a battery life of more than 50 kilometers can be achieved, reducing the frequency of frequent charging. Electric fat tire bikes usually face a more severe working environment - high humidity, low temperature, dust, muddy roads, etc. Therefore, the hub motors used must have the following reliability design, high protection level, excellent waterproof and dustproof performance. Ningbo Yinzhou HENTACH Electromechanical Co., Ltd uses plastic-steel composite gears (5 times the strength of nylon gears), which can withstand long-term continuous torque exceeding 100Nm, with a lifespan of more than 40,000 kilometers, and the closed structure reduces exposed parts, avoids foreign matter intrusion, and reduces later maintenance costs.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd has launched a variety of S-Type series electric fat tire hub motor products, and the product line covers a variety of installation forms such as front wheels, rear wheels, and through-axle structures, including S-Type Pro F1500 front hub motors, S-Type Pro RC / RF rear hub motors, and S-Type R2000 Thru Axle motors. The S-Type Pro F1500 front hub motor has a maximum output power of 1500W and a peak torque of 145Nm, which is suitable for high-load applications such as snow and climbing, and enhances starting traction.

S-Type Pro RC / RF rear wheel hub motor, equipped with 190mm/175mm ultra-wide gear opening, supports cassette or flywheel system, has a stable structure and is suitable for various fat tire frames. S-Type R2000 Thru Axle motor: adopts 12mm through-shaft design to improve stability under high-speed riding, suitable for large vehicles such as Moped and E-Cargo. The flexibility of structural design meets the installation requirements of various models in the E-Fat market.

Traditional nylon gears are prone to wear, slippage and even cracking when the motor power exceeds 1000W and the torque exceeds 100Nm continuously. The plastic-steel composite gear technology independently developed by Ningbo Yinzhou HENTACH Electromechanical Co., Ltd has a strength advantage of more than 5 times and can withstand long-term continuous high torque output of more than 145Nm. The service life exceeds 40,000 kilometers, significantly reducing gear loss and maintenance costs, and is suitable for 1500W high-power systems. It is designed for extreme load and long-range scenarios. This technology solves the problem of short life and durability of high-power motor gears on the market, and has significant competitiveness among high-end E-Fat user groups.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd's multiple models, such as the S-Type F750 and RC rear motor, achieve a balance between weight control and torque output. They weigh only 4.38kg (excluding wheels), which is lighter than the same-level motors on the market, improving the mobility of the vehicle. The torque is over 90Nm, and it can still start easily and climb steadily in muddy, steep slopes and other complex road conditions. It adopts a 36V~60V wide voltage platform design, adapts to a variety of electronic control systems, and enhances the electrical compatibility of the vehicle. This makes Ningbo Yinzhou HENTACH Electromechanical Co., Ltd's E-Fat hub motor not only suitable for high-intensity sports applications, but also for the electrification of small and medium-sized load-carrying transport vehicles.

All Ningbo Yinzhou HENTACH Electromechanical Co., Ltd E-Fat hub motor products have passed the ISO9001 quality management system certification, and some models also support international standards such as CE to ensure the standardization of the production process, the systematization of factory inspection, and the safety and stability of customers.